Optical Bonding

Reliability arises through high-tech, know-how and great attention to detail

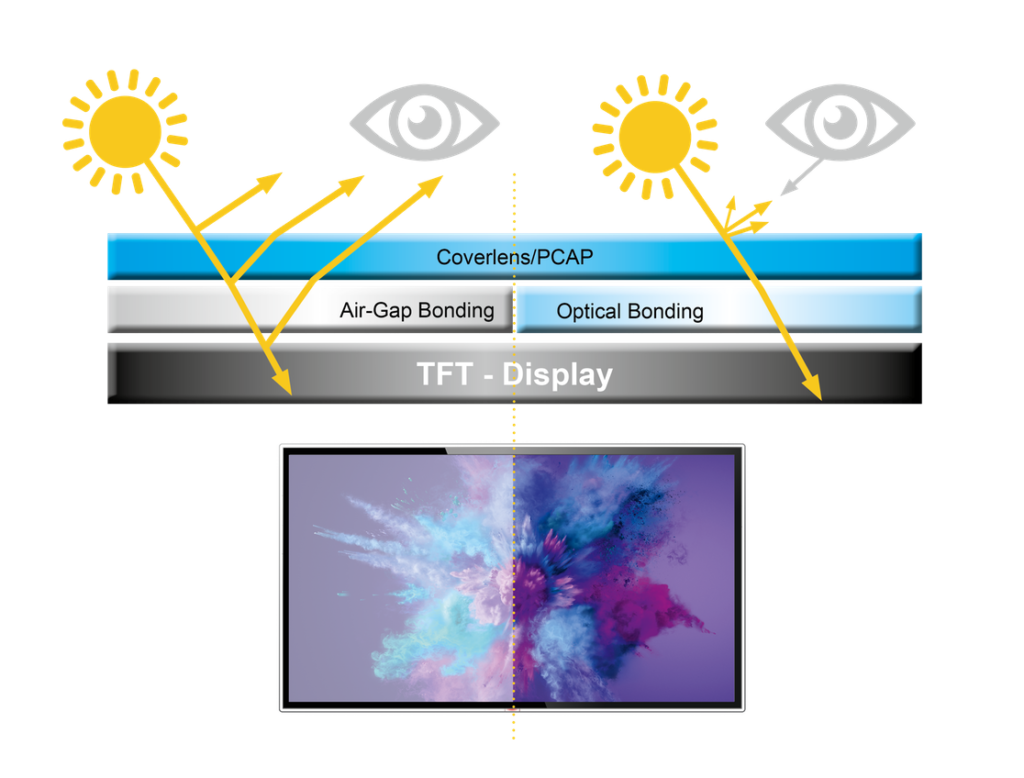

Optical Bonding stands for the full-surface gluing of two rigid, optical elements by means of liquid, highly transparent adhesive (Optical Clear Resin) or adhesive film (Optical Clear Adhesive).

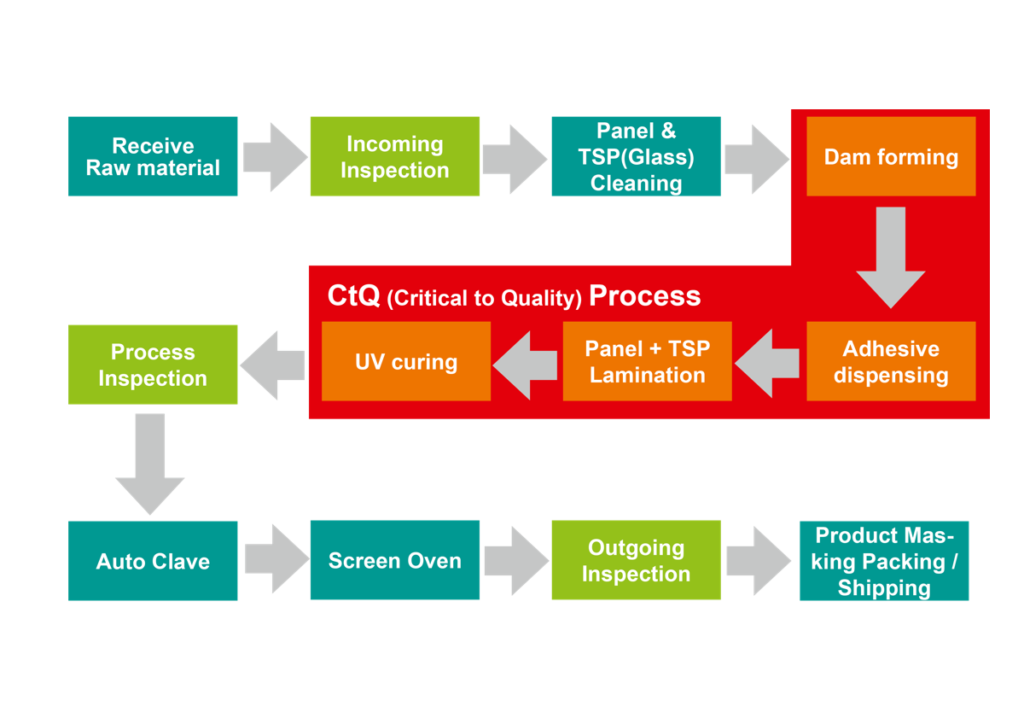

In our case, TFT modules are bonded with PCap / cover glass fronts. For years, we have been working intensively on the subject of optical bonding for displays and have established processes to be able to offer high-quality display bonding for industrial applications. Depending on the manufacturer, TFT modules have different mechanics as well as material properties. Thus, on the one hand, it is necessary to follow a manufacturing approach that is as “tolerant” as possible. Secondly, it is absolutely necessary to have all upstream and downstream production processes in display bonding in order to achieve the long-term quality demanded in the industrial environment. In addition to the absolute cleanness along the entire bonding value chain, this includes the corresponding pretreatment of the components, including surface activation, as well as special post-treatment after bonding. Finally, the choice of the right adhesive is crucial. The TFT modules can be bonded in the original state of the manufacturer (over-frame) as well as without bezel (in-frame).

With Optical Bonding for displays you have all advantages on your side

- Reduction of reflections at the interfaces inside stack-up – 400% increase in sunlight readability

- Improvement of the extrinsic contrast value

- Protecting the display from moisture and dust

- Increased shock resistance – damage in the display and glass / touch composite are significantly minimized

- Higher stability in bumps and falls

- Elimination of parallax from a flat viewing angle

- Visually, everything is on one level; Display frame is no longer visible

- Significantly improved readability of displays with standard brightness in sunlight

We only use adhesives from well-known manufacturers for absolute production reliability

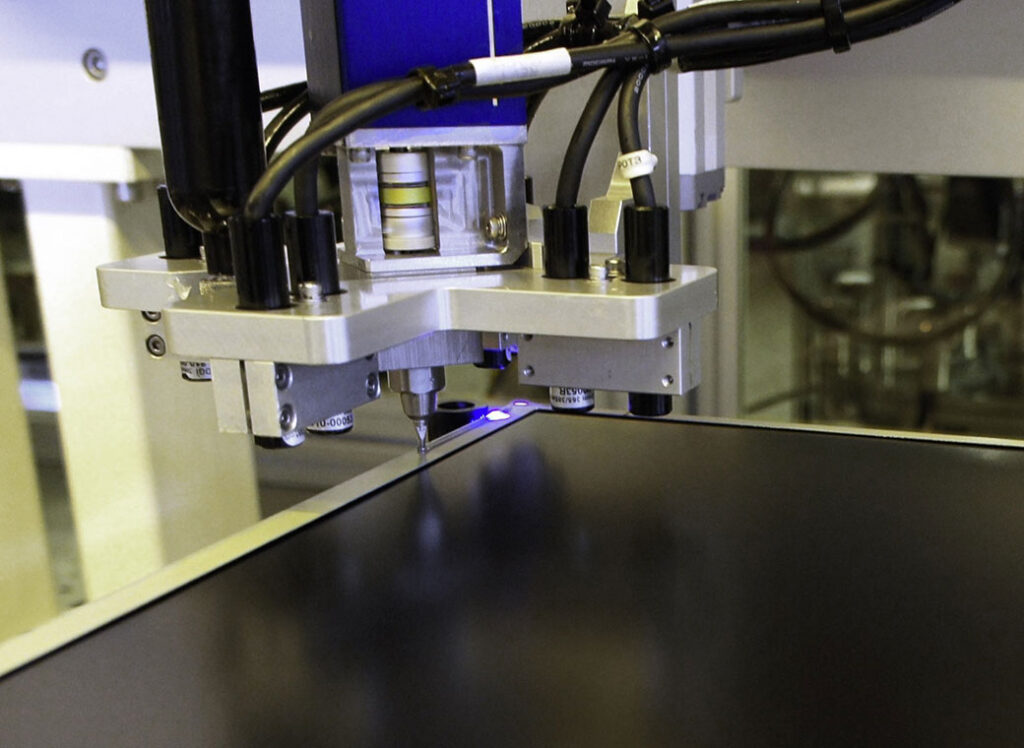

- High process reliability through the use of special materials

- High repeatability, exact alignment

- Bubble-free bonding

- Good viscoelasticity

- No delamination in cold environments

- High adhesion

- For outdoor applications, an “automotive” adhesive is used

- PCap touches based on a glass substrate are optically bonded by OCR to ensure the best possible touch function