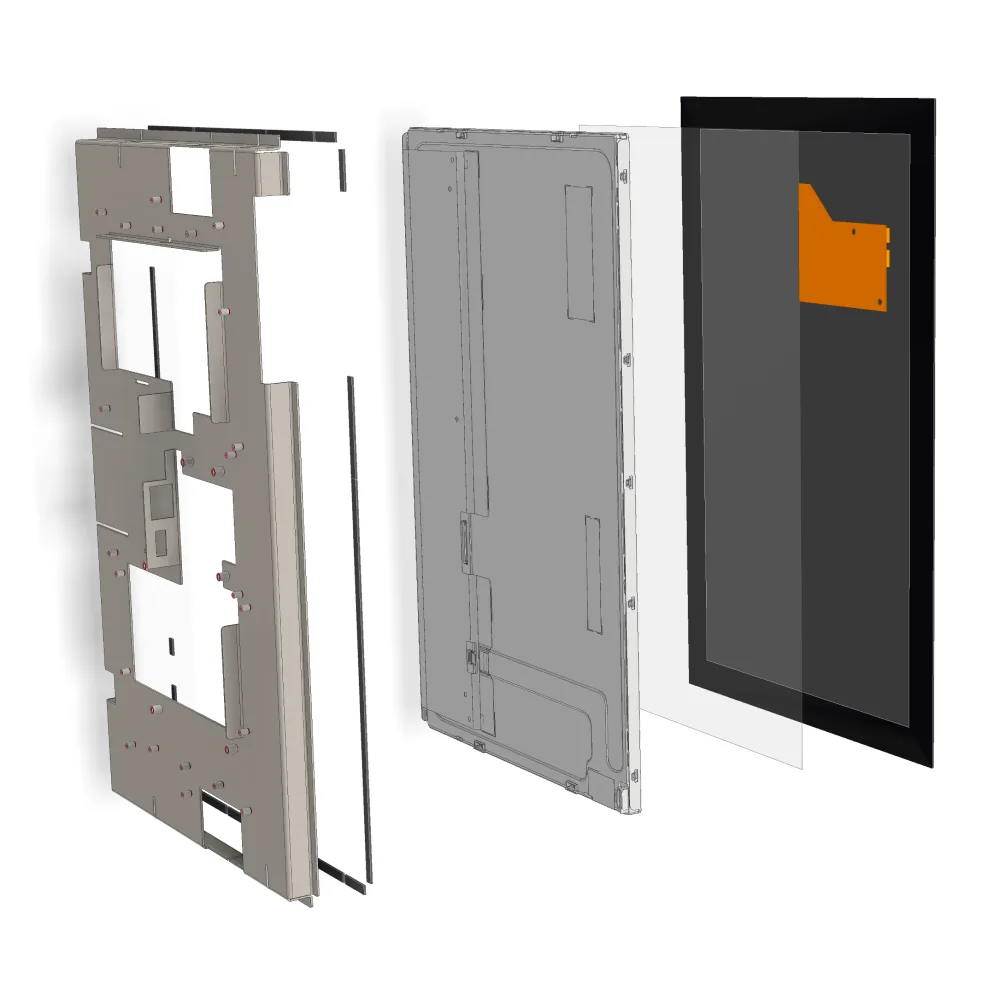

Mechanics & module assembly

Mechanics & module assembly – precise, flexible, designed for industrial use.

We integrate display, touch, cover glass, electronics and housing into robust HMI assemblies.

Custom mechanical design

- Mechanical design and 3D construction in close cooperation with your engineering team

- Design for industrial requirements such as vibration resistance, temperature cycling or IP protection classes

- Consideration of tolerances, joining sequences and assembly steps

Housing construction & module assembly

- Ready-to-install HMI front modules incl. seals, brackets and interfaces

- Achievable up to IP65 / IP67 (e.g. for outdoor or industrial environments)

- Customer-supplied parts (e.g. housings, electronics, fasteners) can be integrated into our processes

- Rapid prototyping using industrial 3D printing

Materials & machining

- Housings and brackets made of aluminium, stainless steel, plastics or hybrid materials

- Precise CNC machining, milling, thread cutting, bending

- Optional: laser cutting for complex 2D geometries (e.g. front panels)

Final assembly & testing

- Integration of display, touch, cover glass, mainboard and housing into a complete system

- Functional tests, visual inspection, final inspection and packaging

- Documentation and traceability according to customer requirements

Note: If you also want to integrate electronics / controllers,

you will find the corresponding services under Mainboards & Kitting.